TECHNICAL SPECIFICATIONS

- Users the liner (foil) from the roll to cut and seal it on the jar automatically.

- The liner adjustment can be done through the touch screen according to the diameter of the jar neck.

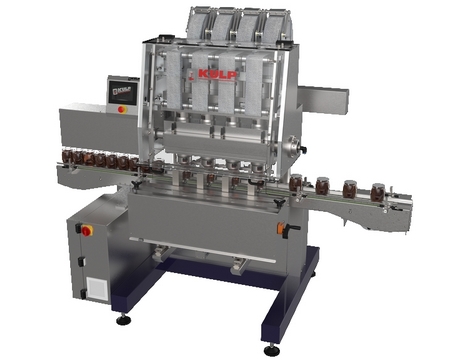

- There are two sealing heads working separately synchronized with each other.

- Easy to change liner rolls.

- Uses conduction sealing.

- Lighted cabin with 10mm polycharbon covers and security switches on the doors.

- No container-No Seal System.

- User friendly touch screen interface available in different languages.

- 3 meters convoyer with adjustable side rails for various sizes of packages.

- The working system is pneumatic and electronic. It operates with 6 bars compressed air.

- The consumption of air is 800 lt/minute when it’s performing with the maximum volume and the maximum speed.

- The electrical connection is three phase (380v / 50-60 Hz)

MATERIALS USED ON THE MACHINE

- The machine is made of 304 L stainless steel and anodized aluminium.

- FESTO Pneumatic Equipments. (Oil-free)

- OMRON PLC, Touch Screen & Drivers.

- SICK Photocells.